Design

Come with an idea, a sample, specifications, and get a professional industrial design within our Mould Cost to Part Cost to Scalability matrix!

- Get free product design consultancy

- We know ideas keep flowing, so we give multiple design revisions

- Reduce your mould costs with good part design

Moulds

The life of every plastic part is the mould, and after understanding your requirements, we provide the most cost-efficient solution for your mould.

- Scalable Injection Moulds

- Moulds starting at, USD 500!

- Moulds designed with Low MOQ's in mind for startups!

Products

We finally manufacture your part, quality check it, and ship it to you so you can focus on whats most important to turn your part into profit, SALES!

- Cost efficient Low MOQ part production

- Ready to Sell packing and packaging services available

- Post sales follow up and support for product modification

Bring Your Idea to shelves, with our manufacturing expertise, FAST!

About Us

Plastic injection moulded product manufacturers since 1985, who breathe injection moulds and plastic parts and are experts at providing high-quality, rapid and end-to-end customer-centric solutions.

Low MOQ experts!

We know how difficult it is to go into an untested market with a large stock pile of already manufactured parts. Get in touch to let us help you with this!

Low mould cost specialists!

Mould costs are the most prohibiting factor for plastic parts, and we are here to change that. Explain us your requirements and we will find you a solution!

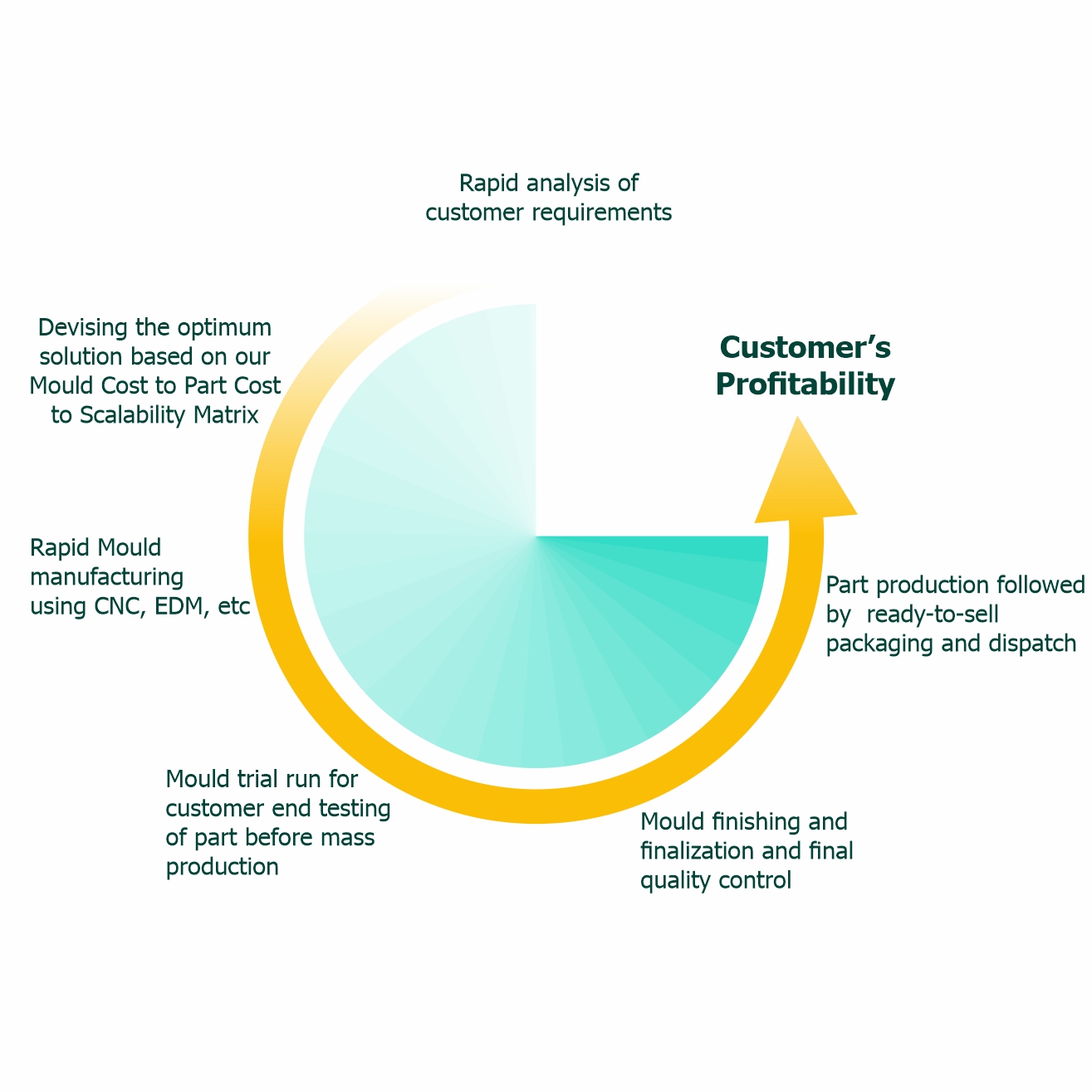

How we deliver

1. Analyse

Rapid analysis of customer requirements and devising the optimum scalable solution for the injection mould.

2. Execute

Immediate execution of your injection mould project with latest manufacturing techniques for low lead time .

3. Produce

Rapid production and shipping of your customized parts to help you get your product in-hand, FAST.

4. Profit

Keeping customer profitability at the center of every decision in the product development cycle for a win-win, always.

What we offer

3D Part Design

We will convert any sketch, specifications or concept into a 3d part design which can be used to make an injection mould.

Prototyping

We offer prototyping services using 3D Printing technology to allow you to test the in hand feel of your product before giving us the go ahead for your mould.

Moulds

Rapid production of your injection moulds tailor made to your requirements for type and quantity of parts and the amount you wish to invest.

Injection moulded parts/components

We also provide manufacturing of the finished part for you and warehouse your mould for free for upto 2 years for seamless fulfilling of repeat orders.

Post process decoration

To increase the perceived value of your product, we also provide post mould decoration of your parts, like hot foil stamping, pad printing, screen printing, etc.

Packing and Packaging

So that you may focus on selling your parts, we also provide packing and packaging services (for e.g. blister packging,etc ) for our clients so that they receive the product in a ready-to-ship condition.

Our delivered projects

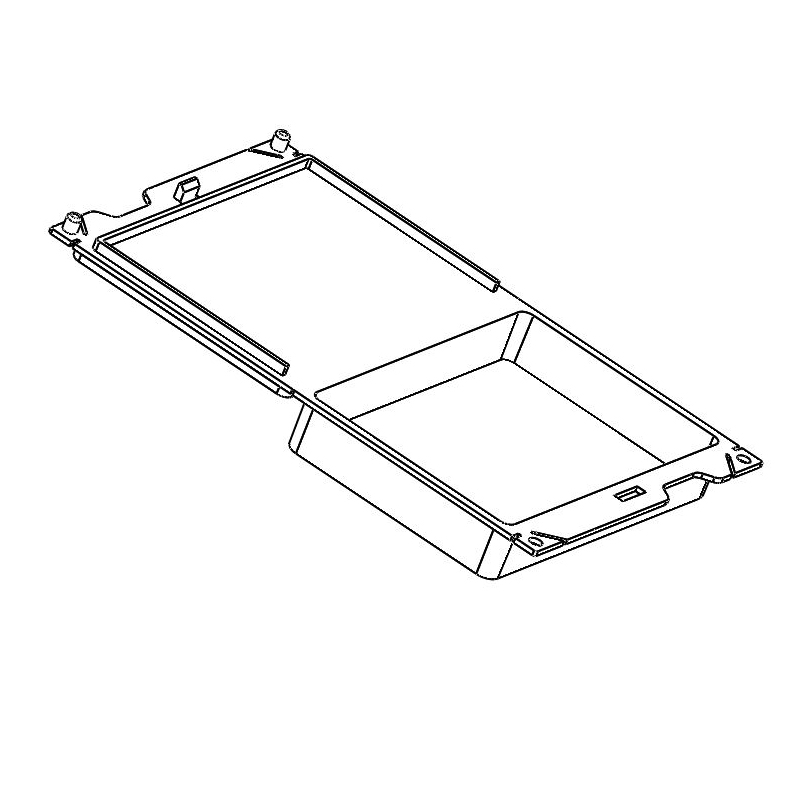

Part from a sample

The customer approached us with a sample, and needed some modifications to it to fit their requirements, while maintaining certain characteristics of the sample part.

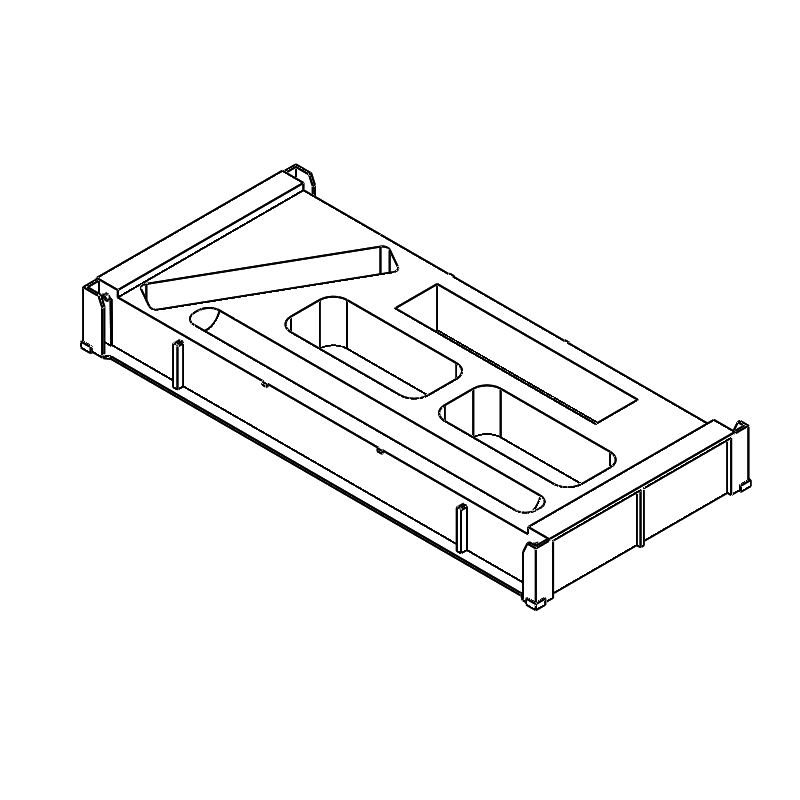

Part from a sketch

A brand manager intending to give a novelty gift based on their company's services for an upcoming trade show, gave us a sketch to develop the product from.

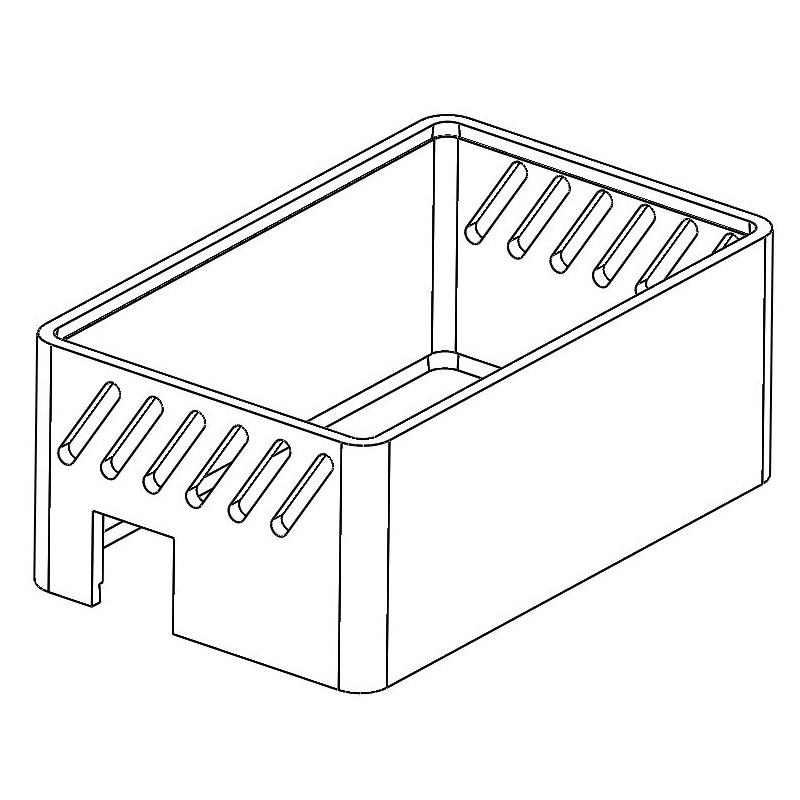

Part from specifications

A technology firm developing a prototype for a card scanner came to us with their messy arduino uno prototype with all its shields and asked us to develop an enclosure for an upcoming presentation.

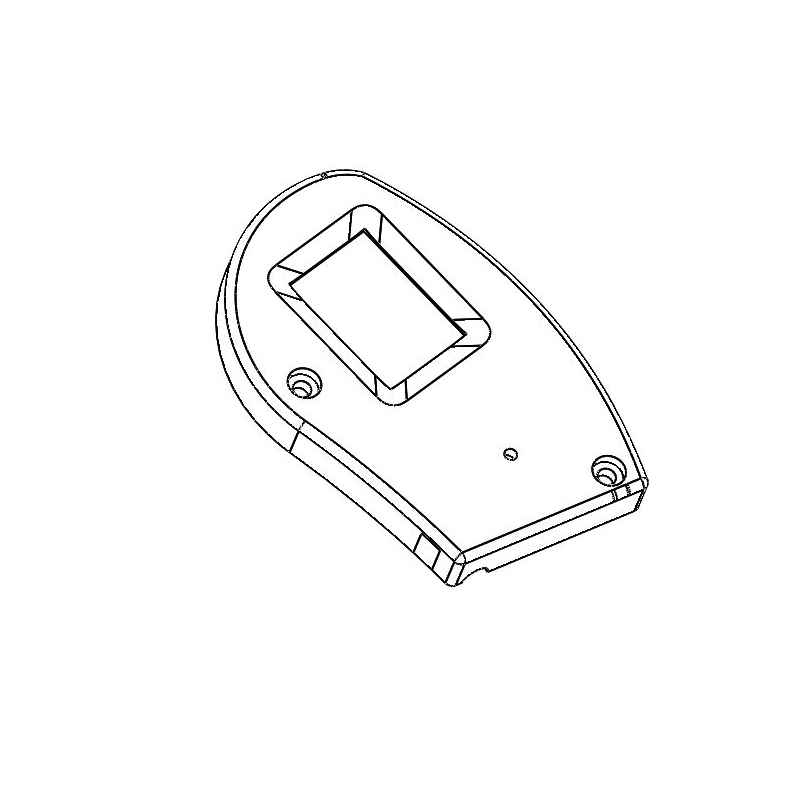

Part from an idea

A company already marketing a product needed to add finger print scanning to their existing product to keep up with competition, and we developed an enclosure which could be affixed onto their existing product and saved large mould costs.

Contact Us

Address

Raj Bharti Plastics Pvt. Ltd. , Plot No.A/33, Street No.3, Opp ESIC Hospital, MIDC, Andheri (EAST), Mumbai - 400093, INDIA

Phone

Email Address